When it comes to solid-liquid separation and dewatering, filter presses are a common piece of equipment used in various industries. However, the pressing cloth, which is a critical component of the filter press, can be expensive and may require frequent replacement. In this article, we will explore some alternatives to the pressing cloth that can help reduce costs and improve efficiency.

Alternatives to Pressing Cloths

Several alternatives to pressing cloths can be used in filter presses, depending on the specific application and industry. Some of the most common alternatives include:

Filter Bags: Filter bags are a popular alternative to pressing cloths, especially in the chemical, pharmaceutical, and food industries. They are made of a porous material that allows for the passage of liquids while retaining solids. Filter bags are easy to install and can be reused multiple times, making them a cost-effective option.

Filter Paper: Filter paper is another alternative to pressing cloths commonly used in filter presses. It is made of a porous paper material that allows for the passage of liquids while retaining solids. Filter paper is a good option for applications requiring a high filtration accuracy.

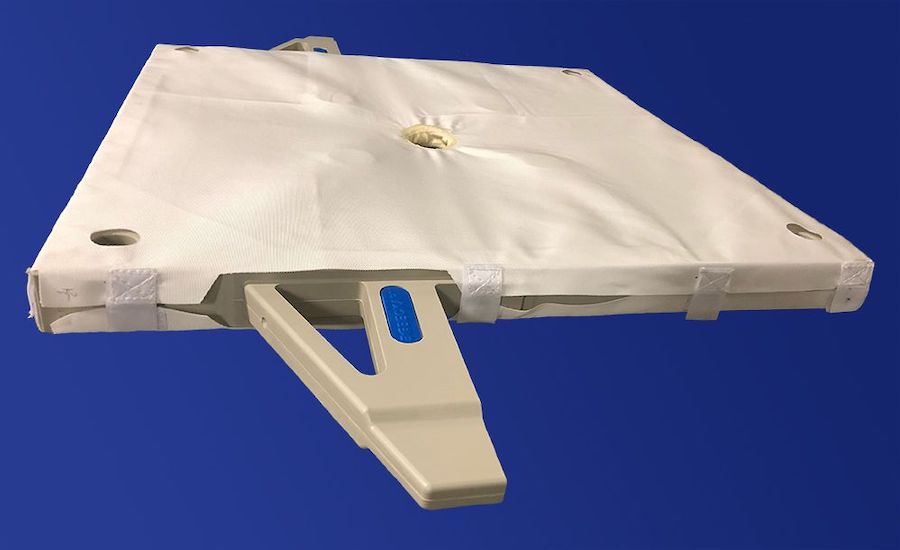

Mesh Filter: A mesh filter is a metal or plastic filter that is made of a mesh material. It is a good alternative to pressing cloths for applications that require a high level of filtration accuracy and durability. Mesh filters can be reused multiple times and are easy to clean and maintain.

Cartridge Filters: Cartridge filters are a popular alternative to pressing cloths in various industries, including water treatment, chemical processing, and food and beverage production. They are made of a porous material that allows for the passage of liquids while retaining solids. Cartridge filters are easy to install and can be reused multiple times, making them a cost-effective option.

Benefits of Alternatives to Pressing Cloths

The alternatives to pressing cloths offer several benefits, including:

Cost-Effectiveness: The alternatives to pressing cloths are often more cost-effective than traditional pressing cloths. They can be reused multiple times, reducing the need for frequent replacement and saving money on maintenance costs.

Improved Efficiency: The alternatives to pressing cloths can improve the efficiency of the filter press by allowing for faster filtration and reducing the risk of clogging.

Better Filtration Accuracy: Some of the alternatives to pressing cloths, such as filter paper and mesh filters, offer better filtration accuracy than traditional pressing cloths, making them ideal for applications that require high-quality filtration.

Easy Maintenance: The alternatives to pressing cloths are often easy to maintain and clean, reducing downtime and improving productivity.

Choosing the Right Alternative

Choosing the right alternative to a pressing cloth depends on several factors, including the specific application, the type of liquid being filtered, and the level of filtration accuracy required. It is important to consider the following factors when selecting an alternative to a pressing cloth:

Compatibility with the Liquid Being Filtered: The alternative to the pressing cloth must be compatible with the liquid being filtered. Some materials may not be suitable for certain chemicals or liquids, so it is important to choose a compatible material.

Filtration Accuracy: The level of filtration accuracy required will determine the type of alternative to the pressing cloth that is chosen. Some applications may require a high level of filtration accuracy, while others may require a lower level.

Durability: The alternative to the pressing cloth must be durable and able to withstand the pressure and wear and tear of the filter press.

Cost-Effectiveness: The alternative to the pressing cloth must be cost-effective and offer a good return on investment.

Conclusion:

In conclusion, there are several alternatives to pressing cloths that can be used in filter presses, depending on the specific application and industry. The alternatives to pressing cloths offer several benefits, including cost-effectiveness, improved efficiency, better filtration accuracy, and easy maintenance.

When choosing an alternative to a pressing cloth, it is important to consider compatibility with the liquid being filtered, filtration accuracy, durability, and cost-effectiveness. By selecting the right alternative to a pressing cloth, industries can improve their solid-liquid separation and dewatering processes, reducing costs and improving productivity.