Galvanized nails and galvanized framing nails both undergo a similar galvanization process, which involves coating the nails with a protective layer of zinc to enhance their resistance to corrosion and rust.

However, there are some differences between the two:

- Application: Galvanized nails are a general term referring to any type of nail that has been coated with zinc for corrosion resistance. They can be used in various applications, including construction, woodworking, and general household repairs. Galvanized framing nails specifically refer to nails designed for framing applications in construction, such as attaching framing members like studs, joists, and rafters.

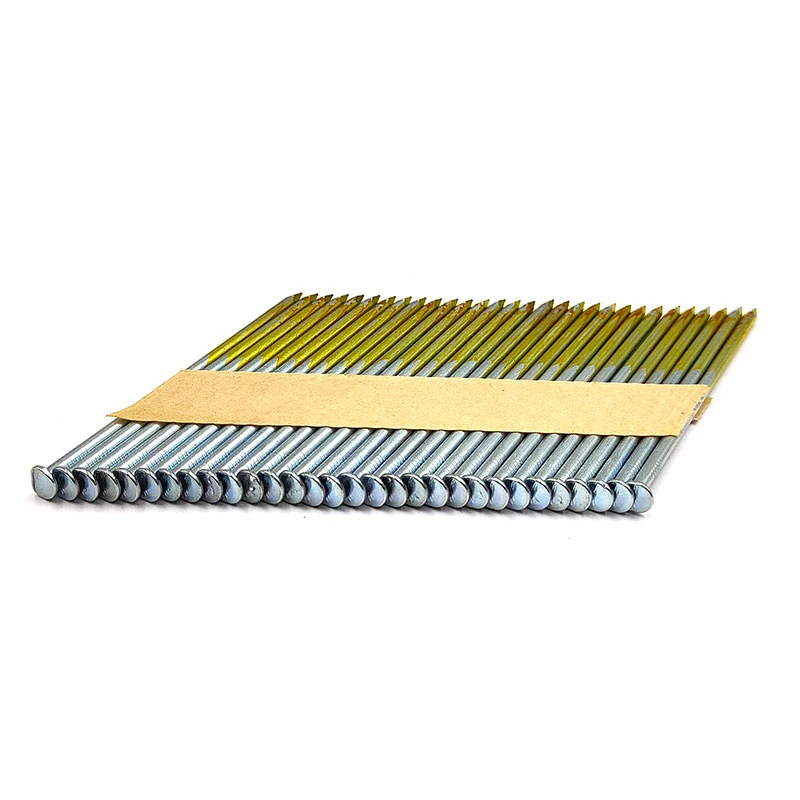

- Size and Shape: Galvanized framing nails are typically larger and heavier-duty compared to standard galvanized nails. They are designed specifically for structural framing tasks and often have a larger diameter and longer length to provide sufficient holding power in load-bearing applications.

- Strength and Durability: Galvanized framing nails are engineered to withstand the heavy loads and stresses encountered in framing construction. They are made from high-quality steel and have a thicker zinc coating to provide enhanced corrosion protection in outdoor and high-moisture environments. Standard galvanized nails may vary in strength and durability depending on their intended use and specifications.

- Usage in Construction: Galvanized framing nails are commonly used in framing and sheathing applications where strength, durability, and corrosion resistance are essential. They are driven into structural lumber with pneumatic nail guns to securely fasten framing members together. galvanized framing nails Standard galvanized nails may be used for lighter-duty tasks such as trim work, siding installation, or general carpentry where load-bearing requirements are not as critical.

- Cost: Galvanized framing nails tend to be more expensive than standard galvanized nails due to their larger size, heavier construction, and specialized design for framing applications. The additional cost reflects the higher performance and durability required for structural framing tasks.

In summary, while both galvanized nails and galvanized framing nails undergo the same galvanization process to protect against corrosion, galvanized framing nails are specifically designed for heavy-duty framing applications in construction and have distinct differences in size, strength, durability, and cost compared to standard galvanized nails used for general purposes.