Discover how to harness the power of steel fibers in concrete applications. This article provides a comprehensive guide on the effective utilization of steel fibers, including proper mixing techniques, dosage considerations, and application methods. Explore the benefits of steel fiber reinforcement and learn how to enhance the strength, durability, and crack resistance of concrete structures. Unlock the full potential of steel fibers to revolutionize your construction projects.

How to Use Steel Fibers in Concrete

Steel fibers offer immense potential for enhancing the performance and durability of concrete structures. This article serves as a comprehensive guide, providing valuable insights into the effective utilization of steel fibers. From mixing techniques and dosage considerations to application methods, learn how to harness the benefits of steel fiber reinforcement to elevate the strength, durability, and crack resistance of your concrete projects.

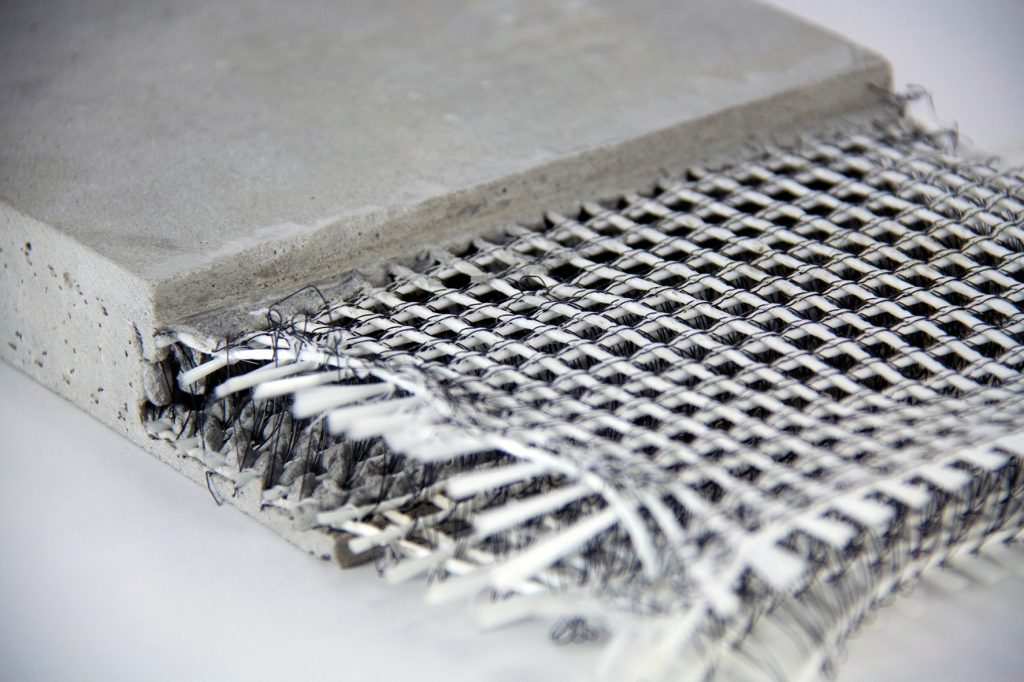

- Understanding Steel Fibers Steel fibers are small, discontinuous fibers made of various steel alloys, typically in the form of short, thin strands or filaments. They are added to concrete mixtures to improve their mechanical properties and performance. Steel fibers offer significant advantages, including increased tensile strength, flexural toughness, impact resistance, and fatigue endurance.

- Proper Mixing Techniques To ensure optimal dispersion and performance, it is crucial to mix steel fibers evenly throughout the concrete mixture. Begin by adding the required amount of water, cement, and aggregates to the mixer. Gradually introduce the steel fibers while continuing to mix until a homogeneous blend is achieved. Avoid excessive mixing times, as this can lead to fiber balling or clumping. Follow the recommended guidelines provided by the manufacturer for the specific type of steel fibers being used.

- Dosage Considerations The appropriate dosage of steel fibers depends on several factors, including the desired performance characteristics and the specific application requirements. Factors such as the type of steel fibers, fiber geometry, concrete mix design, and structural demands must be considered when determining the dosage. Consult with engineers or fiber manufacturers to determine the optimal fiber dosage for your project.

- Application Methods Steel fibers can be applied in various concrete construction methods. In shotcrete or sprayed concrete applications, steel fibers are typically added to the concrete mix and pneumatically projected onto the desired surface. In traditional casting methods, the concrete mixture with steel fibers is poured into formwork and allowed to cure. Alternatively, precast elements can be manufactured with pre-blended fiber-reinforced concrete mixes, ensuring consistent fiber distribution throughout the entire element.

- Case Study: Industrial Flooring Reinforcement An excellent example of steel fiber utilization is in the reinforcement of industrial flooring. By incorporating steel fibers into the concrete mix, the resulting floor exhibits enhanced crack resistance, impact resistance, and load-bearing capacity. Steel fiber reinforcement significantly reduces the occurrence of surface cracks and provides long-term durability, making it an ideal choice for industrial environments subjected to heavy loads and high traffic.

In summary, steel fibers offer remarkable potential in enhancing the performance of concrete structures. By understanding proper mixing techniques, dosage considerations, and application methods, construction professionals can unlock the full benefits of steel fiber reinforcement. Incorporating steel fibers into concrete projects elevates strength, durability, crack resistance, and overall project quality.