In this article, we delve into the dynamic world of the steel fiber market, analyzing its various types, applications, and manufacturing processes. Steel fibers, widely used as a reinforcement material, play a crucial role in enhancing the mechanical properties of concrete and other construction materials. From hooked-end fibers to straight fibers, we explore the different types available and their respective applications. Additionally, we examine the manufacturing processes involved in producing steel fibers, ensuring their quality and efficiency. Join us on this informative journey to understand the pivotal role steel fibers play in shaping the future of construction and infrastructure development.

Introduction The Growing Demand for Steel Fiber Reinforcement

Steel fiber reinforcement has gained immense popularity in recent years due to its ability to improve the strength and durability of concrete structures. This article explores the steel fiber market, shedding light on the various types, applications, and manufacturing processes involved.

Understanding Steel Fiber Types Diverse Solutions for Every Construction Need

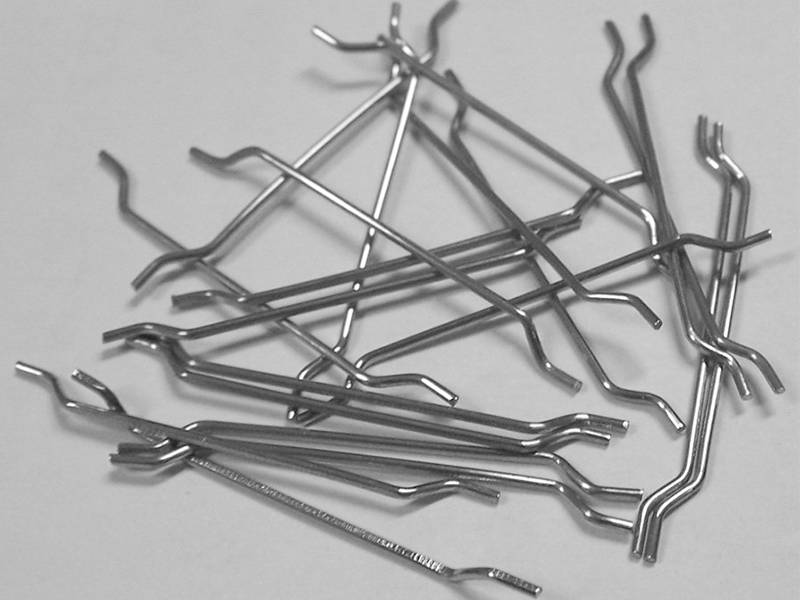

Steel fibers come in a variety of types, each engineered to provide specific properties and functionalities. Hooked-end fibers, with their enhanced anchoring capabilities, find use in high-stress applications such as tunnel linings and industrial flooring. Straight fibers, on the other hand, are preferred for shotcreting and pavement applications. Other variants like crimped fibers and deformed fibers offer unique benefits, catering to a wide range of construction requirements.

Steel Fiber Applications Reinforcing the Foundations of Modern Infrastructure

The applications of steel fibers are widespread and ever-expanding. In infrastructure projects, steel-fiber-reinforced concrete (SFRC) is utilized to strengthen bridges, highways, and airport runways, enhancing their load-bearing capacity and resistance to cracking. In the industrial sector, SFRC finds use in constructing warehouses, storage tanks, and industrial flooring that endure heavy loads and traffic. Moreover, in the field of underground constructions, such as subway tunnels, steel fibers significantly improve the tunnel lining’s structural integrity.

The Steel Fiber Manufacturing Process Precision and Consistency for Optimal Performance

The manufacturing process of steel fibers involves a series of precise steps to ensure the desired mechanical properties are achieved consistently. The process starts with selecting high-quality raw materials, followed by wire drawing and cutting stages. Mechanical or hydraulic processes are then employed to add specific features to the fibers, depending on the desired type. Stringent quality control measures are implemented throughout the manufacturing process to deliver reliable and performance-driven steel fibers.

Advantages and Examples of Empowering Construction with Reinforced Steel Fibers

The advantages of steel fibers extend beyond enhanced structural integrity. They offer quicker construction cycles and cost-effectiveness compared to traditional reinforcement methods like rebar. For instance, in the construction of a large warehouse floor, steel fibers facilitated faster construction and provided superior crack control, ensuring a longer-lasting and robust flooring solution. In another example, the use of steel fibers in precast concrete elements significantly improved their flexural strength, making them suitable for a wider range of applications.

Market Outlook and Growth Factors Paving the Way for a Resilient Future

The steel fiber market is expected to witness substantial growth in the coming years, driven by the growing demand for sustainable and resilient infrastructure. Governments and construction companies worldwide are increasingly adopting steel fiber-reinforced solutions due to their longevity and cost-effectiveness. Additionally, advancements in manufacturing technologies and the development of innovative fiber types will further fuel market expansion.

Conclusion Steel Fiber: Strengthening Infrastructures, Enriching Lives

In conclusion, the steel fiber market plays a pivotal role in enhancing the durability and performance of modern infrastructure. With its diverse types, wide-ranging applications, and precise manufacturing processes, steel fibers empower the construction industry to build robust and resilient structures. As the demand for sustainable construction solutions grows, steel fibers will continue to revolutionize the way we reinforce our world for a stronger and safer future.